Location:Home > Attention

Quality matters:

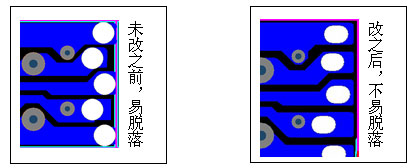

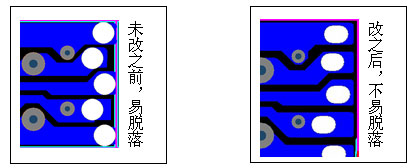

First, for products that are often moved, easy to vibrate, etc., the copper skin falls off:

a. The wire terminal should not be too close to the side; (as attached)

b. In addition, punch a threading hole near the welding wire to let the welded wire pass through this hole, reducing direct external force pulling;

c. If there is a position, add copper area around the solder joint to increase the tensile force around it;

d. Use a soft or fine spot welding wire.

e. When inserting, insert the component feet to the end, do not leave the component feet floating;

f. Temperature and time control are in place during welding, and one welding is successful. .

In this way, the situation that the welding point is easy to fall off is basically avoided;

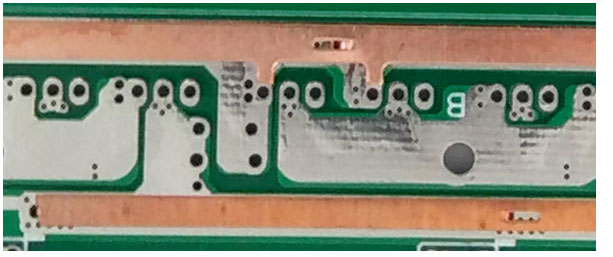

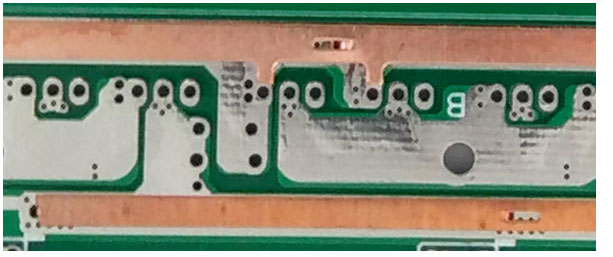

About the thickness of copper foil

a. For high-current boards, 36um and above copper foils are needed for the production, but the amount of current carried by the copper foil of the board is very small. If there is a large current, it is recommended to use copper bars and copper sheets to increase the current intensity. As shown below:

b. It is used for general low current products. It is produced with 18um or less copper foil blanking, with better performance. For example, the surface of the double panel is 36um of copper. After plating, the hole copper is generally 18um, and the surface copper is 36um + 18um = 54um. Where the surface copper and hole copper meet, a bottleneck is formed, where the current encounters resistance, which is prone to problems.

About Banqiao:

a. FR-4 sheet is made of glass fiber cloth, glue, copper, etc. When a single panel has a large copper surface on one side and no copper on the other side, it will cause an uneven tension on the two sides; for a double panel, the copper foil on both sides is unevenly distributed;

b. Vertical spraying of tin, first come out, when the temperature exceeds 130 ° C, the board will deform, and uneven heating and cooling will cause the board to warp.

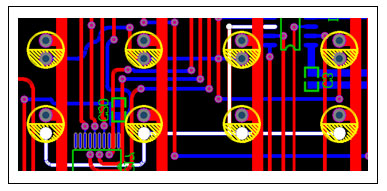

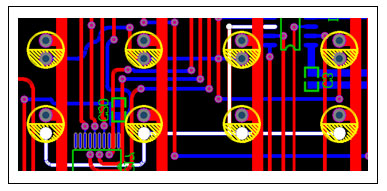

Fourth, about vias.

When the current through this via is relatively large, please make more vias near this via. For example, in the lamp board, when one IC controls multiple lamp beads, please make a few more vias in the control circuit where the vias are required. As shown in the figure, add a few more vias in the middle of the lighting circuit:

Five, about tin plate tin connection

When the surface adopts a tin spraying process, when the IC pin pitch is less than 0.2mm, the two IC pins are easily broken, and a gold process can be used.

Six, single-sided double-sided solder mask ink is easy to plug holes

When non-copper surface is printed with solder resist oil, the 0.4mm solder mask range can be enlarged at the edge of the hole to avoid ink blocking.

First, for products that are often moved, easy to vibrate, etc., the copper skin falls off:

a. The wire terminal should not be too close to the side; (as attached)

b. In addition, punch a threading hole near the welding wire to let the welded wire pass through this hole, reducing direct external force pulling;

c. If there is a position, add copper area around the solder joint to increase the tensile force around it;

d. Use a soft or fine spot welding wire.

e. When inserting, insert the component feet to the end, do not leave the component feet floating;

f. Temperature and time control are in place during welding, and one welding is successful. .

In this way, the situation that the welding point is easy to fall off is basically avoided;

About the thickness of copper foil

a. For high-current boards, 36um and above copper foils are needed for the production, but the amount of current carried by the copper foil of the board is very small. If there is a large current, it is recommended to use copper bars and copper sheets to increase the current intensity. As shown below:

b. It is used for general low current products. It is produced with 18um or less copper foil blanking, with better performance. For example, the surface of the double panel is 36um of copper. After plating, the hole copper is generally 18um, and the surface copper is 36um + 18um = 54um. Where the surface copper and hole copper meet, a bottleneck is formed, where the current encounters resistance, which is prone to problems.

About Banqiao:

a. FR-4 sheet is made of glass fiber cloth, glue, copper, etc. When a single panel has a large copper surface on one side and no copper on the other side, it will cause an uneven tension on the two sides; for a double panel, the copper foil on both sides is unevenly distributed;

b. Vertical spraying of tin, first come out, when the temperature exceeds 130 ° C, the board will deform, and uneven heating and cooling will cause the board to warp.

Fourth, about vias.

When the current through this via is relatively large, please make more vias near this via. For example, in the lamp board, when one IC controls multiple lamp beads, please make a few more vias in the control circuit where the vias are required. As shown in the figure, add a few more vias in the middle of the lighting circuit:

Five, about tin plate tin connection

When the surface adopts a tin spraying process, when the IC pin pitch is less than 0.2mm, the two IC pins are easily broken, and a gold process can be used.

Six, single-sided double-sided solder mask ink is easy to plug holes

When non-copper surface is printed with solder resist oil, the 0.4mm solder mask range can be enlarged at the edge of the hole to avoid ink blocking.